TEL:

0373-6372968-

CONTACT US

Mingyang Machinery Equipment

TEL:0373-6372968 6372969

FAX:0373-5755777

CONTACTS:Mr. Zhu

PHONE:159 0303 3385

E-MAIL:1139537703@qq.com

ADDRESS:GuGuZhai town industry gathering area, Xinxiang city Henan province

BUS LINE:Take a bus to Xinxiang City for pick-up and delivery!

UPDATA:2017-11-25

HITS:10466次

PECULIARITY:Pneumatic conveyin...

Process specification:

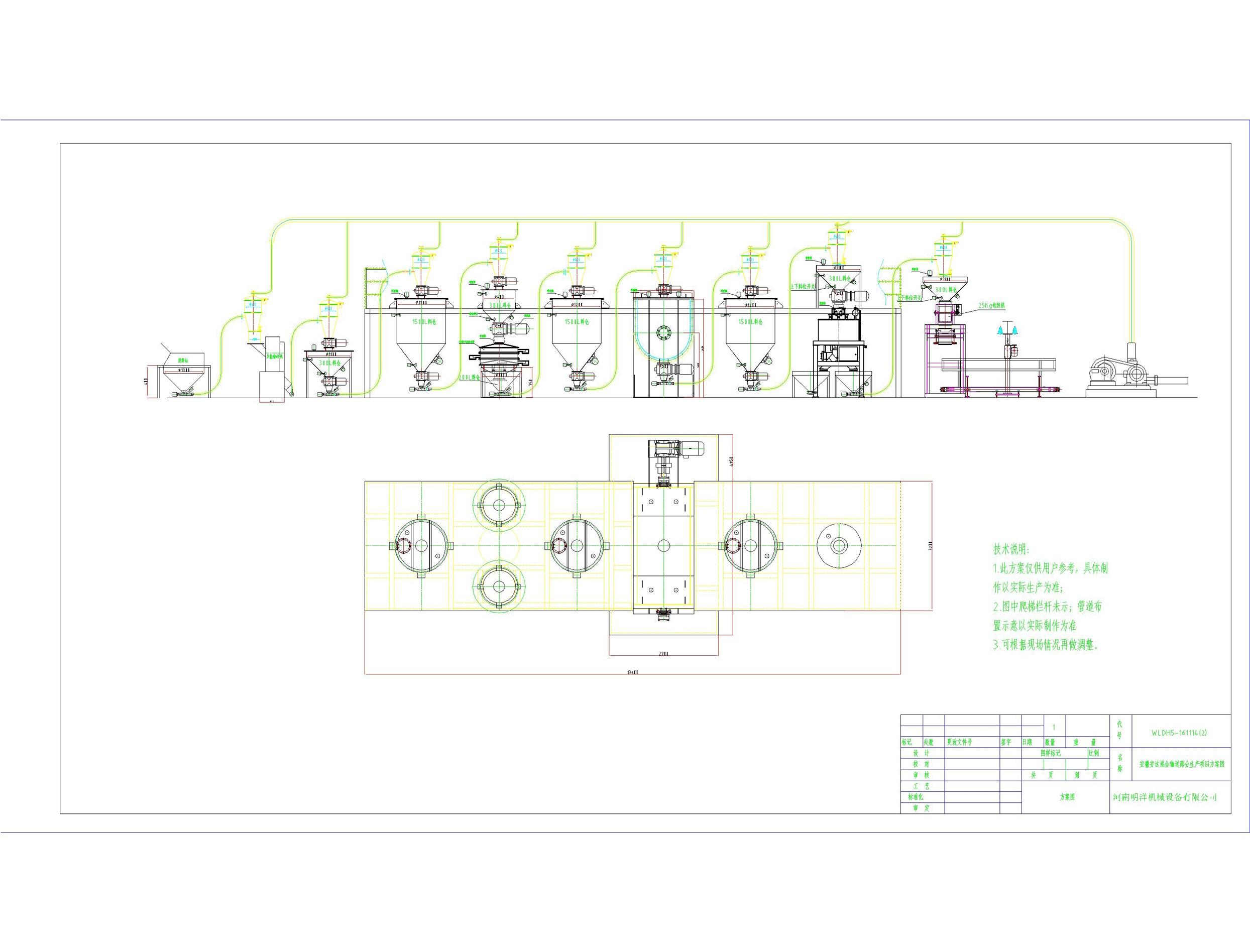

The crusher's material is processed by feeding crusher of No. 1 pneumatic conveyor. The crushed material is fed into No. 2 and No. 3 silos through vacuum conveying of No. 2 and No. 3. The material is evenly conveyed to No. 2 and No. 3 vibrating screens by fork feeders into small silos (No. 2 buffer). Material, No. 3 buffer material, and then (No. 4 vacuum conveyor) to convey the material to the mixing equipment, when the material reaches the mixing load, the vacuum conveyor stops. Then the mixer starts to run (mixer set time). The mixed material is placed in the lower buffer bin. First, the starter butterfly valve is opened and the material is conveyed to the packaging machine (No. 4 buffer) by (No. 5 vacuum conveyor). Material) The final measurement packaging.

Electric power description of production line:

The mixer is 11KW*1, the crusher is 4KW*1, the vacuum transmission of No.4 is 5.5KW*1, No.1, No.2, No.3 and No.5 are 3KW*4, the fan is 0.75KW*4, the vibration screen is 1.1KW*4, the permanent magnet iron removal is 0.75KW*1+1.5KW*1.

Product characteristics:

A: Siemens S7 series PLC is used to control the field equipment. Schneider low voltage electrical apparatus ensures stability.

B: The whole process has automatic manual function, action flow display, fault and alarm display.

C: Complete report functions: computer records the actual measurement value of each batch of raw materials, mixing temperature, mixing time, output statistics, etc. If there are problems in the product, you can query the mixing process from the historical records;

D: All raw materials can be measured automatically and accurately, and only one person is needed to reduce the labor intensity of workers. All operations can be completed.

E: Toledo Weighing Sensor and Display Instrument. The measurement accuracy is not less than 0.3%.

F: This scheme has fewer dust, less labor, lower energy consumption and higher automation in the field.More cost-effective

Structural sketch:

The official website of our company's related equipment, please check and browse.:

http://www.myzhendongshai.com/(Mixer website) http://www.zhendongshai-my.cn/index.php(Pneumatic conveying website) http://www.mingyangsf.com/(Comprehensive website)

| Last article: | Multi-point suction pneumatic conveying under negative pressure |

| Next article: | Positive pressure dense phase pneumatic conveying |

Yugong Network Security, No. 41072102000531

Yugong Network Security, No. 41072102000531