TEL:

0373-6372968-

CONTACT US

Mingyang Machinery Equipment

TEL:0373-6372968 6372969

FAX:0373-5755777

CONTACTS:Mr. Zhu

PHONE:159 0303 3385

E-MAIL:1139537703@qq.com

ADDRESS:GuGuZhai town industry gathering area, Xinxiang city Henan province

BUS LINE:Take a bus to Xinxiang City for pick-up and delivery!

UPDATA:2017-11-25

HITS:58070次

PECULIARITY:...

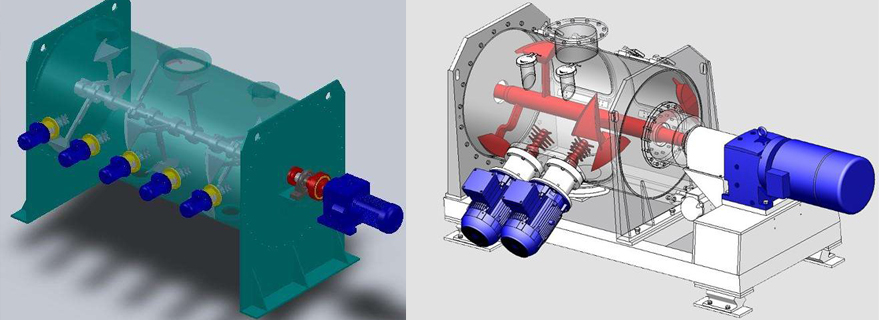

Product Description:

The product can be used for mixing powder and powder,powder and liquid,powder and paste; It has the high speed fly-cutter dispersanteffect,so that the processing materials in the function of ploughshare and fly-cutter can achive the uniform mixing in a short time,especially formixing the materials of powder and paste,powder and fibre materials.It can meet uniform mixing of the calciun carbonate and cotton,flour and lard.You also can choose the different mixing blades according to the different processing materials.It is widely used in food, medicine, cosmetic,plastic,, titanium pigment etc.

Product video:

Technical Parameters:

|

Model |

Machine Volume (L) |

Production Volume (L/Batch) |

Mixing Volume (Kg/Batch) |

Main Power (Kw) |

Speed of mainshaft(R/min) |

Flying Power (Kw) |

Flying speed(R/min) |

Dimension (mm) |

Weight (Kg) |

|

LDH-100 |

100L |

30~80 |

<100 |

3 |

60 |

1-1.5Kw |

1440R/min or 2880R/min |

1500*500*700 |

500 |

|

LDH-200 |

200L |

50~150 |

<150 |

4 |

60 |

1-3Kw |

2000*600*900 |

700 |

|

|

LDH-500 |

500L |

150~400 |

<300 |

7.5 |

41 |

2-3Kw |

2500*800*1200 |

1600 |

|

|

LDH-1000 |

1000L |

300~800 |

<600 |

11 |

41 |

2-3Kw |

2700*1000*1450 |

2100 |

|

|

LDH-2000 |

2000L |

500~1500 |

<1200 |

15 |

33 |

3-5.5Kw |

3400*1200*2700 |

2800 |

|

|

LDH-4000 |

4000L |

1000~3200 |

<2500 |

30 |

33 |

4-5.5Kw |

4100*1400*2000 |

4500 |

|

|

LDH-6000 |

6000L |

2000~4500 |

<3000 |

37 |

28 |

4-5.5Kw |

4500*1500*2200 |

5800 |

|

|

LDH-10000 |

10000L |

3000~8000 |

<5000 |

45 |

28 |

6-5.5Kw |

6000*1800*2500 |

9500 |

|

|

LDH-15000 |

15000L |

5000~11000 |

<8000 |

70 |

17 |

7-5.5Kw |

6500*2000*2800 |

13000 |

|

|

LDH-20000 |

20000L |

6000~15000 |

<10000 |

90 |

17 |

8-5.5Kw |

7500*2400*3000 |

15500 |

|

|

LDH-30000 |

30000L |

10000~24000 |

<12000 |

110 |

15 |

10-5.5Kw |

9000*2600*3500 |

21000 |

Performance introduction:

1.Flexible Material Selection Scheme

Mixer can be customized with carbon steel, manganese steel, 304 stainless steel, 316L stainless steel, 321 stainless steel and other materials, and different materials can also be used in combination.When choosing material, the equipment should be distinguished: the contact part with material and the non-contact part with material; the coating or protective layer with the functions of anti-corrosion, anti-bonding, isolation and wear resistance can also be added in the mixer; the surface treatment of stainless steel should be divided into sand blasting, wire drawing, polishing and mirror surface treatment, and can be applied to different parts of the mixer.

2.Reliable Driver Configuration

The mixer is equipped with driving devices with different capacity, power and output speed according to material properties, starting mode and mixing mode. The selection of driving motors includes: ordinary motor, riot-proof motor, frequency conversion motor, high efficiency and energy-saving motor, high protection level motor, and motor under different voltage.Commonly used reducer: R, K, F series gear reducer, cycloid pinwheel reducer, universal gear reducer, planetary gear reducer; commonly used connection mode: direct connection, pulley connection, hydraulic coupler connection.

3.Efficient agitator

The plough head of the plough mixer is removable and can be replaced quickly. The plough knife is wear-resistant, which is more suitable for the working condition with faster wear. Mixers can also be equipped with different mixers according to different material properties. Spindle agitator: ordinary plough type, serrated plough knife, scraper shaver; high-speed shearing flying knife: multi-blade cross knife, double-leaf lotus knife;

4.Excellent discharging device

Horizontal plough mixer is usually equipped with pneumatic curved flange valve. When the valve closes, the curved flange of the valve fully fits the cylinder arc. In the mixing process, there is no excessive stirring dead angle, so that the mixture material is more uniform. Valve drive can be divided into manual, pneumatic and electric three kinds. Valves for reference include powder spherical valves, drum valves, plum blossom dislocation valves, powder butterfly valves, rotary feeding valves, etc.

5.Powerful ancillary components

The mixer can be equipped with various components, such as coil steam jacket, honeycomb pressure jacket, circulating medium jacket, on-line sampling valve, high-speed flying knife, temperature detection, weighing system, dust removal and purification, etc. The jacket of mixer adopts different forms of jacket according to different heat source medium. It can be heated and cooled, and the temperature is within 250 degrees Celsius.

When adding a small amount of liquid, spray spray device is needed, which is more conducive to the dispersion of liquid evenly in the main material.

The spray system consists of three basic modules: pressure source, liquid storage tank and spray head.

6.Close dynamic shaft seal

Mixer design three sealing modes: packing seal, combined gas seal, mechanical seal; to solve the particle, powder, micron powder, liquid, slurry state of the spindle seal.

Structural sketch:

Selection method:

1. Determine the volume of each batch of mixed materials, ranging from 0.1 to 20 cubic meters, and select the equipment of corresponding specifications.

2. Select equipment to make material. Material composition: contact with material, not contact with material, other parts of equipment to maintain the original material.

Material quality is determined by material properties, working conditions, sanitary grade and other factors. Conventional carbon steel and 304/316L/321 stainless steel are used.

After material selection, surface treatment requirements are determined according to requirements.

3. Determine the driving capacity of the configuration according to the specific gravity and fluidity of the material and the start-up standard. Start standard points: overload startup, no-load startup.

4. According to the actual process conditions, add auxiliary functional components, such as spraying, heating/cooling, etc.

5. Opening requirements of design equipment, such as feeding port, cleaning port, exhaust hole, etc.

6. Choose discharge mode and drive mode, separately manual, pneumatic and electric.

Important Note: The selection of equipment is an important link. We should provide detailed information of materials and process arrangement as far as possible so that our company professionals can provide you with high-quality technical services.

The official website of our company's related equipment, please check and browse.

http://www.myzhendongshai.com/(Mixer website)

http://www.zhendongshai-my.cn/index.php(Pneumatic conveying website)

http://www.mingyangsf.com/(Comprehensive website

| Last article: | Double cone mixer |

| Next article: | No more. |

Yugong Network Security, No. 41072102000531

Yugong Network Security, No. 41072102000531